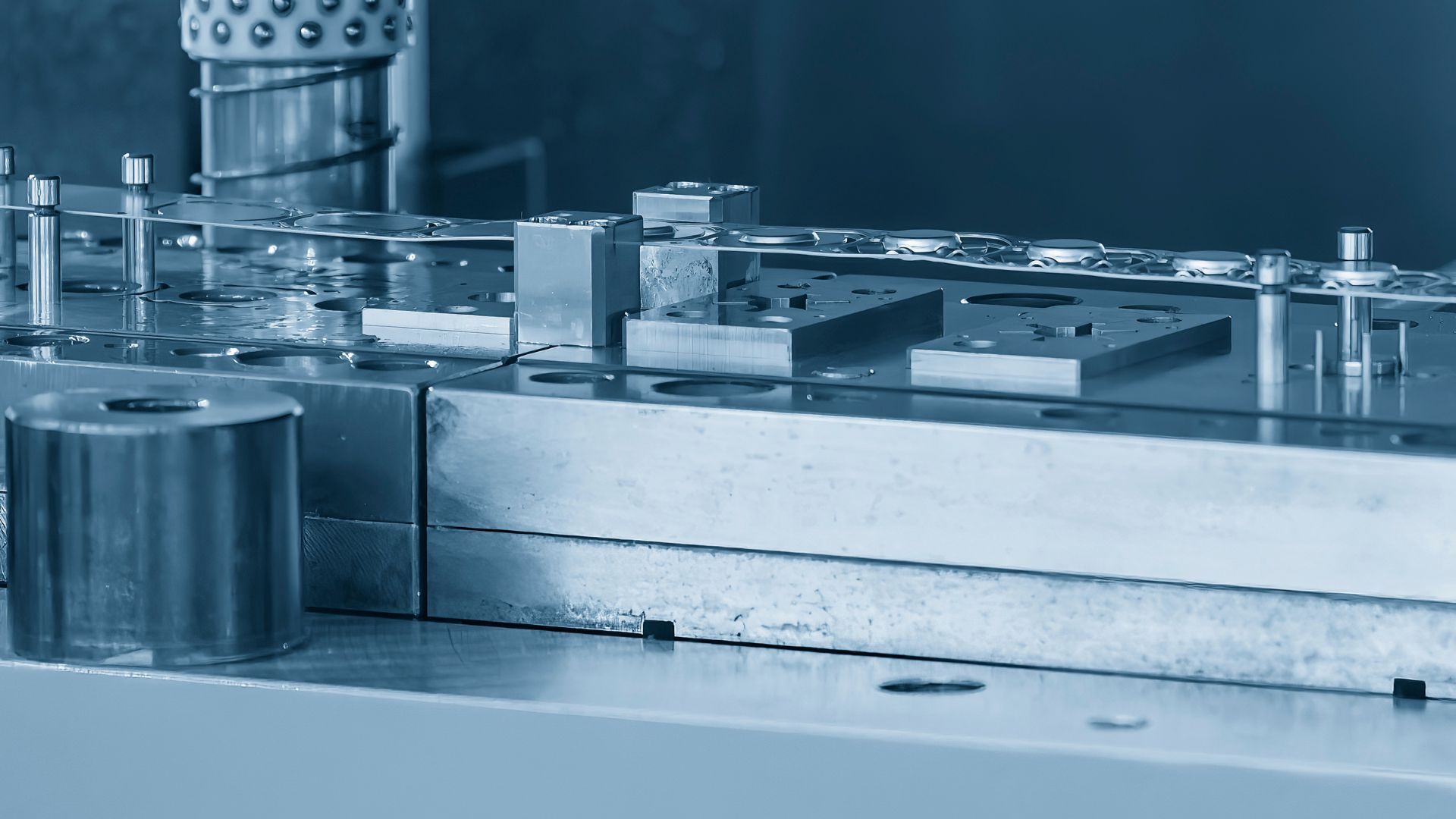

Progressive Stamping

& Precision Die Manufacturing

Progressive Stamping

& Precision Die Manufacturing

Our progressive stamping and die manufacturing services deliver high-precision, high-volume metal components with exceptional consistency and efficiency. From in-house die design and engineering to fabrication and production, we utilize advanced tooling, tight tolerances, and rigorous quality controls to ensure repeatable accuracy on every part. Ideal for complex components and long-run production, our progressive stamping solutions reduce cycle times, minimize material waste, and maintain superior quality from prototype to full production.

Benefit from Comprehensive Services

Micro-Technic offers a comprehensive range of services, including tool and die making, stamping, machining, and more. Our all-in-one facility allows us to manage projects from start to finish under one roof, ensuring efficiency and quality.

Our Experienced

and Skilled Team

The strength of Micro-Technic lies in our experienced team. We retain the finest talent in the industry to ensure top-quality results for our customers. Our professionals are committed to meeting and exceeding your expectations. Give us a call to discover the expertise our team brings to every project.

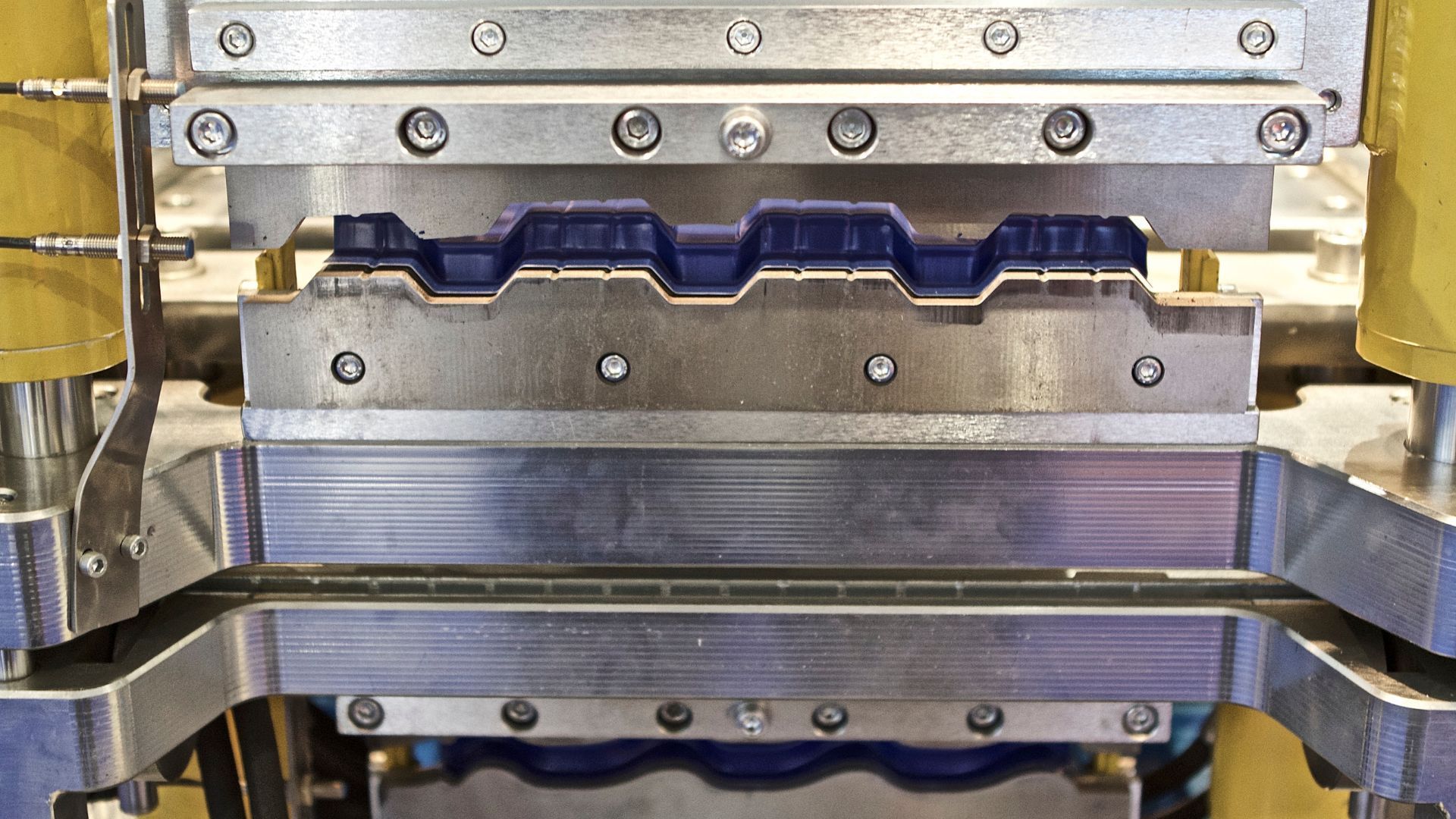

Efficient Progressive Stamping Solutions

We design our progressive stamping services to efficiently and cost-effectively produce complex parts for you. Utilizing high-speed, industry-leading presses, we can handle high-volume production with consistent quality. From design to the final product, we ensure every detail meets your specifications. Give us a call to learn more about our progressive stamping capabilities and how they could be exactly the process your formed parts need.

High-Accuracy

Precision Machining

Micro-Technic excels in precision machining, providing high-accuracy components tailored to your specific needs. Our skilled machinists utilize the latest CNC technology to produce intricate parts with exceptional detail. We ensure that each piece meets your exact specifications, so we're here to meet your needs no matter what industry you are in.

Give us a call now to get a quote or explore our precision machining services.

Quality assurance is paramount at Micro-Technic. Our rigorous QA inspection process (ISO 9001-compliant) ensures that every product meets the highest standards of quality and precision. Using advanced measurement tools and techniques, we verify that each part complies with your specifications. Contact us to learn more about our comprehensive QA inspection services.

Rigorous QA

Inspection Processes

Discover Our

Advanced Facilities

Our 4,200 sq. ft. climate-controlled facility is equipped with presses, mills, and other assorted technology to handle your manufacturing projects. With 24-hour security and a wide array of tools, mills, and presses, we ensure a safe and efficient environment for production.

Contact Micro-Technic Tool & Stamping today to schedule a full rundown of our advanced facilities or learn more below.

Send us a Message today

Have a question? We’re here to help! Send us a message, and we’ll be in touch as soon as possible.

FAQs

Why is Micro-Technic Tool & Stamping so popular?

Micro-Technic Tool & Stamping is a leading tool & die manufacturer in Santa Ana, CA, known for our commitment to quality and precision. As a tool & die manufacturer, we utilize cutting-edge technology and advanced manufacturing processes to deliver exceptional products. Our reputation as a reliable tool & die manufacturer is built on our ability to handle projects from conception to completion under one roof. Our clients trust us to manufacture tools & dies because we maintain strict quality control measures and ensure timely delivery. Additionally, our experienced team of fabrication professionals and trusted QA experts reinforces our standing as a premier tool & die manufacturer in the industry.

What does Micro-Technic Tool & Stamping offer?

At Micro-Technic Tool & Stamping, we offer a comprehensive suite of manufacturing solutions designed to meet the diverse needs of our clients. Our expertise spans from the initial design and conceptualization stages, utilizing advanced 3-D CAD design software, to the precision fabrication of intricate components. Our state-of-the-art facilities and highly skilled team enable us to handle complex stamping, machining, and detailed cutting processes with exceptional accuracy. We also ensure rigorous quality assurance throughout every step of production, guaranteeing that our final products meet the highest standards of excellence and reliability.

How can I contact Micro-Technic Tool & Stamping?

Contact us today to receive assistance with any inquiry. Call our office during work hours at 714-545-0223, and our team will promptly answer your questions. For more thorough inquiries, you can also contact us at gdavie@microtechnic-stamping.com, or use our on-site contact form.